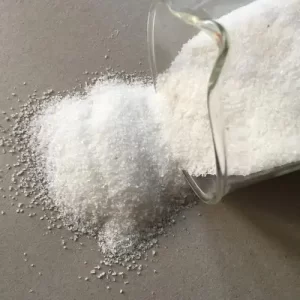

What is polyacrylamide ?9

Polyacrylamide (PAM) is a collective term for homopolymers of acrylamide or copolymers with other monomers. (PAM) Polyacrylamide is one of the most widely used water-soluble polymers. Polyacrylamide (PAM) is widely used in industries such as petroleum extraction, papermaking, water treatment, textiles, pharmaceuticals, and agriculture. According to statistics, 37% of the total global production of PAM polyacrylamide is used for wastewater treatment, 27% for the petroleum industry, and 18% for the paper industry.

The usage of Polyacrylamide:

Widely used in departments such as water treatment, papermaking, petroleum, coal, mining, geology, textiles, and construction.

- Cationic polyacrylamide (CPAM) is used as a flocculant in wastewater treatment for industries such as mining, metallurgy, textiles, and papermaking. Used in various operations in the petroleum industry.

- Application of Anionic Polyacrylamide (APAM): Anionic polyacrylamide is used for flocculation and precipitation in industrial wastewater (electroplating plant wastewater, metallurgical wastewater, steel plant wastewater, coal washing wastewater, etc.).

- Non ionic (NPAM) polyacrylamide uses: clarification and purification, sedimentation promotion, thickening and other effects, filtration promotion. It can fully meet the requirements of various fields in waste liquid treatment, sludge concentration and dewatering, mineral processing, coal washing, papermaking, etc. Simultaneously using non-ionic polyacrylamide and inorganic coagulants (such as polymeric ferric sulfate, polymeric aluminum chloride, iron salts, etc.) can demonstrate greater effectiveness.

Application of zwitterionic polyacrylamide (ACPAM):

- Profile control and plugging agent.After oilfield testing, the performance of this new zwitterionic profile control and plugging agent is higher than other single ion properties of profile control and plugging polyacrylamide agents.

2. In many cases, the combination of anionic polyacrylamide and cationic polypropylene produces a significant and synergistic effect when treating sewage and water compared to using only one type of ionic polyacrylamide. If used improperly, both of them will produce white sediment and lose their effectiveness. So using composite ion polyacrylamide yields better results

Characteristic precautions

- Flocculation; PAM can neutralize suspended substances through electrical neutralization, bridge adsorption, and flocculation.

- Adhesive properties: It can achieve adhesion through mechanical, physical, and chemical actions.

- Resistance reduction: PAM can effectively reduce the frictional resistance of fluids, and adding a small amount of PAM to water can reduce resistance by 50-80%.

- Thickening: PAM has a thickening effect under both neutral and acidic conditions. When the pH value is greater than 10, PAM is easily hydrolyzed and forms a semi network structure, resulting in more significant thickening.

Introduction to the working principle of PAM:

- Principle of flocculation: When PAM is used for flocculation, it is related to the surface properties of the flocculated material, especially the dynamic potential, viscosity, turbidity, and pH value of the suspension. The dynamic potential of the particle surface is the reason for particle blockage. Adding PAM with opposite surface charges can reduce the dynamic potential and cause coagulation.

- Adsorption bridging: PAM molecular chains are fixed on different particle surfaces, forming polymer bridges between particles to form aggregates and settle.

- Surface adsorption: Various adsorption of polar functional groups particles on PAM molecules.

- Enhancement effect: PAM molecular chains and dispersed phases are linked together through various mechanical, physical, chemical, and other interactions to form a network, thereby enhancing the effect.

Advantages of partnering with Prime Chemicals for polyacrylamide:

- Quality is More Stable

During polyacrylamide production, the quality is hard to be controlled due to various factors like formula, raw materials and production technology, and this may lead to huge difference in final use effect.

- Models are More Applicable

For more than 10 years, we have been specializing in the development of polyacrylamide for end markets and the models it developed are more suitable for the end markets. For each client, we will organize R& D to customize polyacrylamide models for specific sewage and sludge.

- Model selection is More Precise

There is no best polyacrylamide, but the most polyacrylamide. The performance of polyacrylamide depends on whether the model selection is accurate or not and it has much to do with the selection range. The wider the range is, the easier it will be to select the most suitable model.

- More Cost-effective

Help the customer select a suitable model with lower price to save cost. At the same time, selecting a precise model can reduce the amount of usage and finally lower the cost.